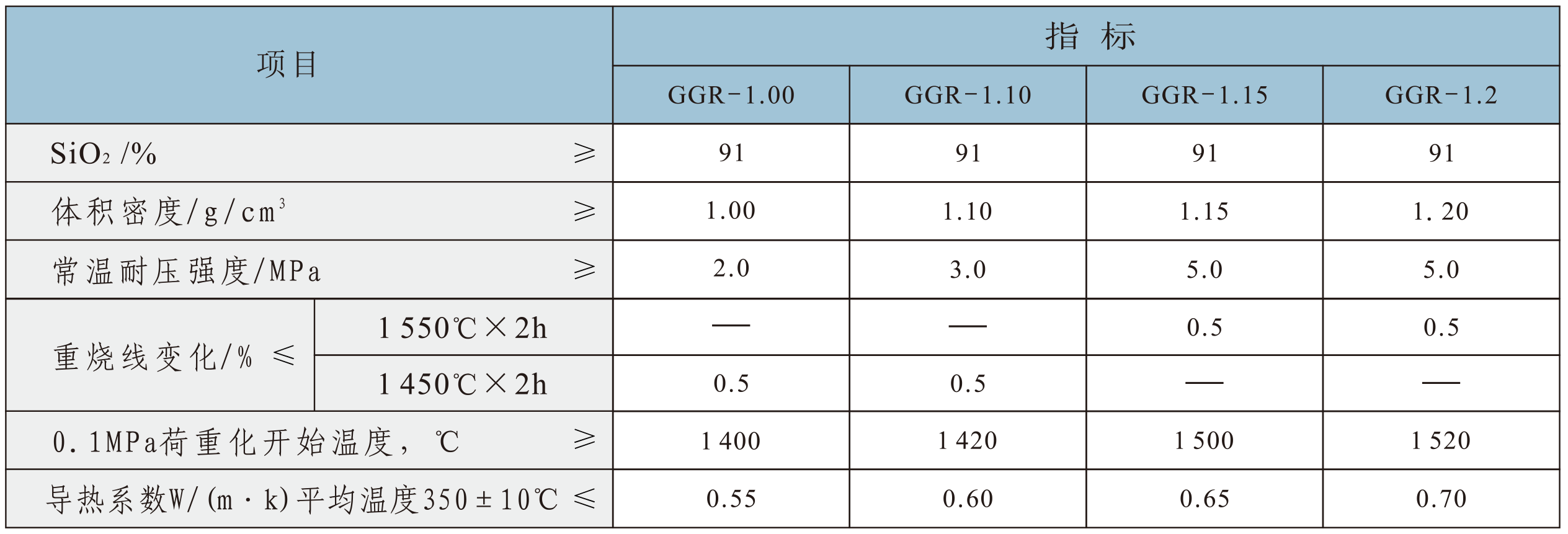

Also known as silica insulation brick. Lightweight refractories with silica above 91% and bulk density below 1.2g/cm3. The refractoriness and load softening temperature are not much different from ordinary silicon bricks with the same composition. However, due to the large number of pores, the compressive strength, slag resistance, and corrosion resistance are not as good as those of ordinary silicon bricks, but the thermal shock resistance has been improved.

Using finely divided silica as raw material, the critical particle size is usually not more than 1mm, and the particles less than 0.5mm are not less than 90%. Add flammable substances to the ingredients or use the gas generation method to form a porous structure, which is obtained by firing. Can also be made into non-burning products. It is mainly used in various parts of the kiln that require heat insulation or reduce its own weight without direct contact with the melt, without the action of aggressive gases, or with sudden temperature changes. When used at high temperature, it must not be in contact with alkaline refractories. According to different materials, the maximum service temperature is 1200~1550℃.

Clay 19 hole brick

Mullite-cordierite brick

Mullite-cordierite brick

Anchor brick